This model came from a semi-trailer kit. I converted the semi-trailer into a NASCAR hauler, adding a refrigeration unit and an interchangeable manual and electrical working ramp.

Materials

Processes

A visit to the local lamborghini dealership

This project required in-person field research. There was a Lamborghini dealership nearby, and I'd been trying to see a NASCAR hauler up close but could never see them at the hours I passed by.

But one Saturday morning, on an early walk with my wife, we spotted a driver and hauler delivering a new car to the Lamborghini dealership.

The driver was friendly and keen about the project. He showed me around the hauler and let me take pictures. It turned out that he had to move an antique car from the top level to the bottom, so there was plenty of time to watch how the mechanisms worked, to study the structure and to ask questions.

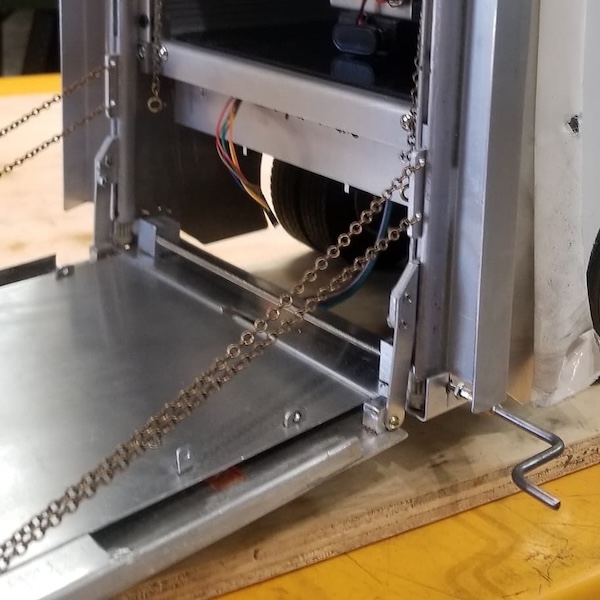

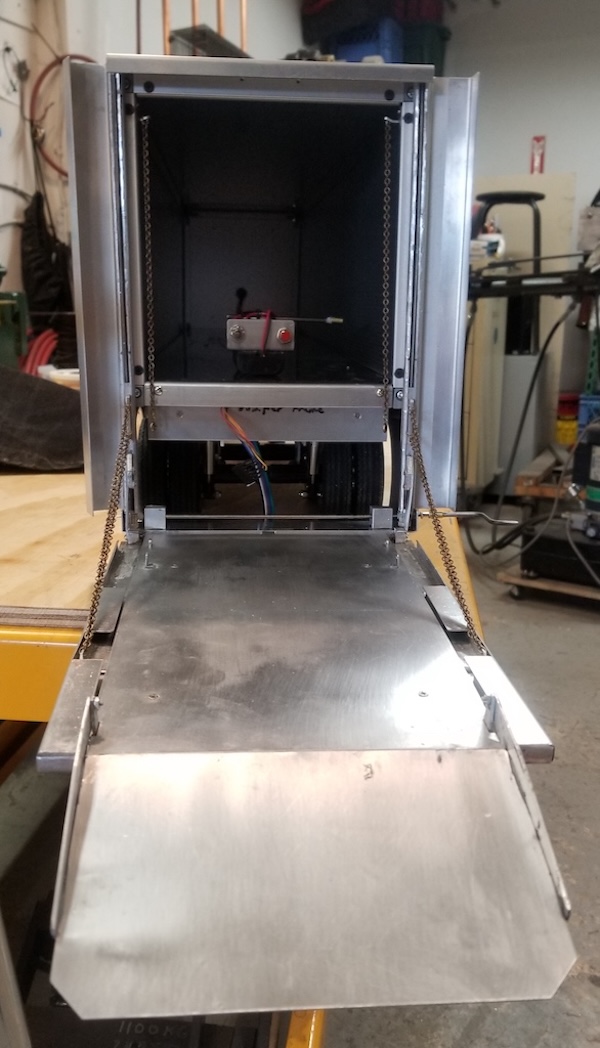

This close-up study helped me accurately replicate the ramp.

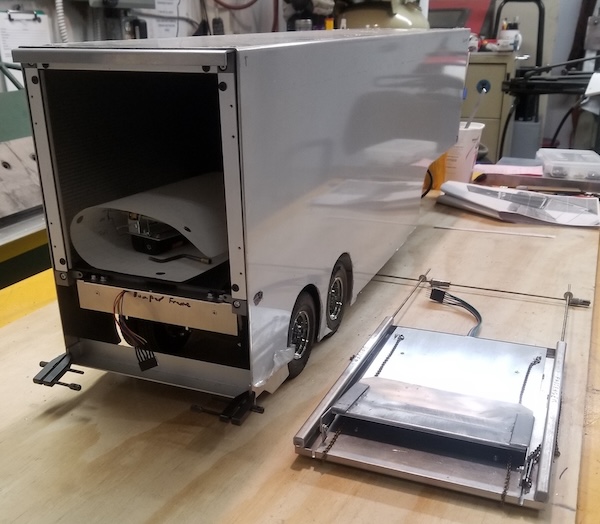

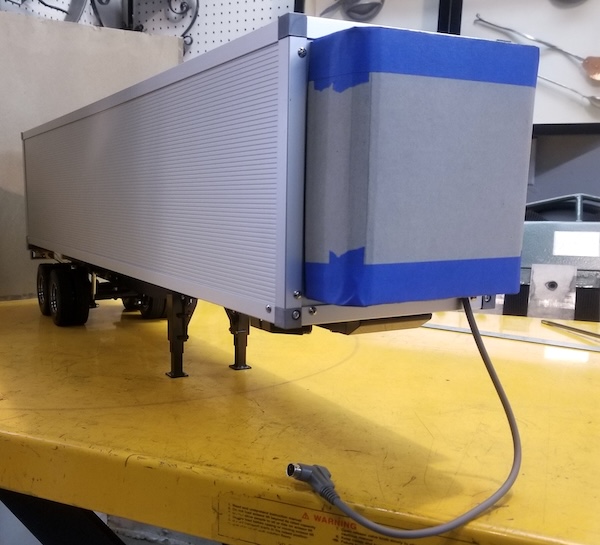

Reefer unit and electronic ramp

To fabricate the reefer (refrigeration) unit, I drew it from a pattern and then cut it out from sheet aluminum. Then, I hammer-molded the round edges, welded the seams and screwed the reefer unit to the trailer. I also added pavement bumpers to the rear door, (which was also the ramp) and reflectors.

To create the electronic components and the drive for the ramp, I used an AA-size battery pack, a switch, a miniature gear reducer unit and extra gears.

By the end of the project, the ramp on this model could be raised and lowered by hand or by a battery-powered mechanical drive - just like the actual haulers.

After many weeks, the model's owner came to take it away. I had sent him pictures, and he'd come by weekly to see the progress. Completing this project was bittersweet, as it was not my model, and I enjoyed my client's weekly visit.

Thanks as always to @hobbiesmagicbox and Lee's Electronics.

Stages of the fabrication